The Impact of AI in Manufacturing: Unleashing Productivity

Visual inspection powered by machine learning algorithms can also track whether workers on the production floor are wearing safety gear and adhere to health and safety regulations. The technology can also monitor the workers’ fatigue levels and take necessary measures if they appear to be exhausted. Manufacturing companies can use AI in various ways to improve safety on the production floor. The first example of such application – already mentioned in the context of energy efficiency – is lighting automation. Using it, they can respond to real-time demand for lighting, brightening up particular areas once it’s needed.

AI technology even offers manufacturers benefits like guided buying and supplier risk management. In this article, we’ll discuss the types and applications of AI in manufacturing, the challenges of integrating AI into production processes, and the future of manufacturing AI. In this dynamic landscape, AI is not an end in itself; it’s a means to an empowered future.

AI for Digital Marketing: Benefits and Applications

To guide you in capitalizing on AI capabilities, we’ve provided this video to show you how AI can help you on the shop floor and listed some of the benefits of AI for manufacturing. AI can integrate data from various sources, including machines and sensors, to optimize manufacturing processes and increase yield in continuous processes. AI-powered cameras and sensors can quickly identify defects and errors in the manufacturing process, leading to increased first-pass yield. Using large language models to extract textual information from reports, refined through quantitative measures, can improve QC modeling outputs. Businesses have already started modernizing their processes and implementing such strategies to reduce operational cost and improve efficiency. It’s time to hire an Android app developer to help you automate the process by implementing the AI technologies in your factories.

However, within manufacturing itself, there is a significant potential for using AI in other tasks outside production lines. This requires a step-by-step investigation into the problems that resulted in the defect. With the help of AI, you can connect incidents, automatically surface causes, and assist managers in quickly getting to the root causes. This will allow them to focus on addressing problems rather than sifting through documentation. Akira AI helps increase revenue growth, innovation, and operations excellence by implementing AI in manufacturing companies. Akira AI provides a unique combination of SHAP, IME, PDP/ICE, Anchors, and Rules extraction methodologies in interactive dashboards to explain the models.

What Is Artificial Intelligence in Manufacturing?

AI-powered computer vision cameras continuously monitor work to see that adherence to safety procedures like wearing Personal Protection Equipment (PPE). Computer vision powered by AI can automatically monitor and alert supervisors when proper safety procedures or equipment is not utilized. AI can be used to understand the data created by sensor technologies like IoT.

Manufacturers can leverage NLP for better understanding of data gained with the help of a task called web scraping. AI can scan online sources for relevant industry benchmark information, as well as costs for transportation, fuel, and labor. A term that often gets thrown around related to artificial intelligence and robotics is robotic processing automation.

Advantages and Disadvantages of Artificial Intelligence

Leveraging AI and machine learning, manufacturers can improve operational efficiency, launch new products, customize product designs, and plan future financial actions to progress on their digital transformation. For example, certain machine learning algorithms detect buying patterns that trigger manufacturers to ramp up production on a given item. This ability to predict buying behavior helps ensure that manufacturers are producing high-demand inventory before the stores need it. One big advantage of cobots over traditional industrial robots is that they are cheaper to operate as they don’t need their own dedicated space in which to function. This means they can safely work on a regular plant floor without the need for protective cages or segregation from humans. They can pick components, carry out manufacturing operations like screwing, sanding, and polishing, and operate conventional manufacturing machinery like injection molding and stamping presses.

- They can also carry out quality control inspections using computer vision-enabled cameras.

- Speaking about manufacturing, we should consider the high cost of suspending production especially dealing with big enterprises.

- It also minimizes unplanned downtime of machinery, reduces maintenance costs, and extends the lifespan of machinery.

- High-value, cost-effective AI solutions are more accessible than many smaller manufacturers realize.

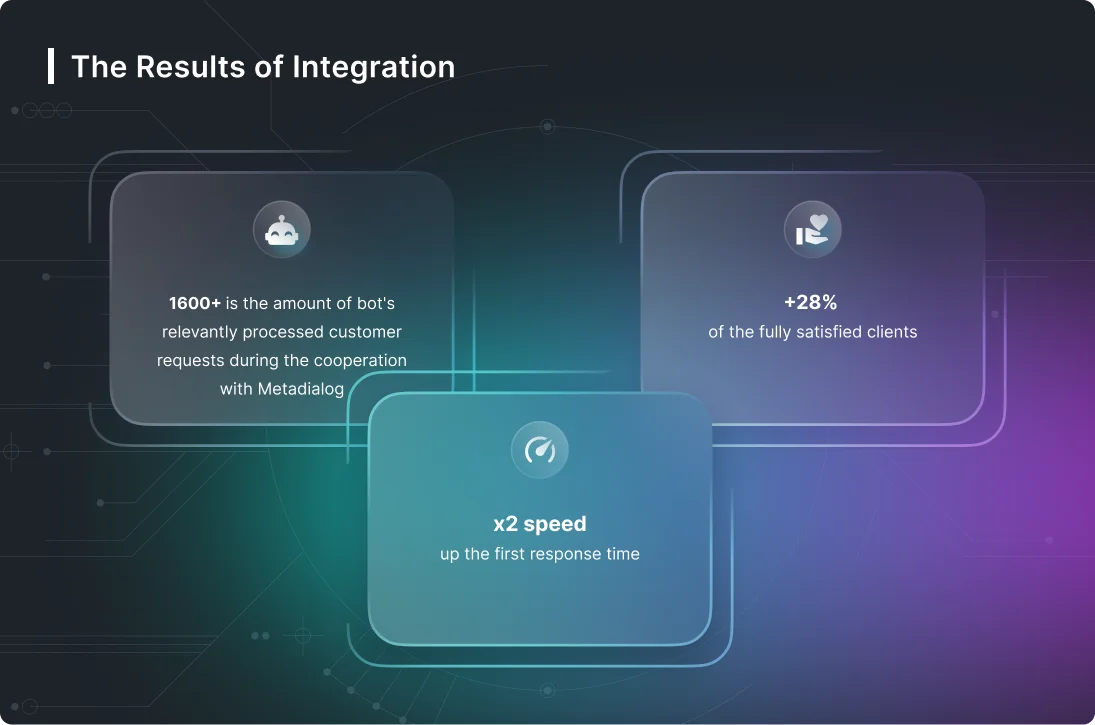

Read more about https://www.metadialog.com/ here.